When you’re shipping products to customers, plastic mailers have been the default choice for good reason—they’re cheap, lightweight, and keep your products safe. But as more customers push for eco-friendly options and environmental concerns grow, finding alternatives to traditional plastic packaging isn’t just good for the planet—it’s becoming good for business too.

I’ve talked with dozens of small business owners who feel stuck between wanting to be more sustainable and needing packaging that’s affordable and practical. The good news is that the gap between those goals is closing fast.

Let’s break down the realistic options you have right now, with honest talk about costs, performance, and which products work best with each alternative.

Why More Businesses Are Moving Beyond Traditional Plastic

Before diving into alternatives, it helps to understand why this shift is happening:

- Customer expectations are changing. A vast majority of consumers now say they’re willing to pay more for sustainable packaging. For younger customers especially, your packaging choices can make or break their decision to purchase from you again.

- Brand image matters more than ever. In a crowded marketplace, your packaging is a physical representation of your brand values. Sustainable packaging tells customers you care about more than just profit.

- The plastic problem is very real. Only about 9% of all plastic ever produced has been recycled. The rest ends up in landfills, oceans, or as microplastics in our environment—and consumers are increasingly aware of this.

- Regulations are tightening. Many cities and states are implementing plastic bans or restrictions. Getting ahead of these changes now can save you headaches later.

- Shipping costs keep rising. Lightweight alternatives that protect products effectively can help manage these expenses.

Now let’s look at what’s actually working for businesses similar to yours.

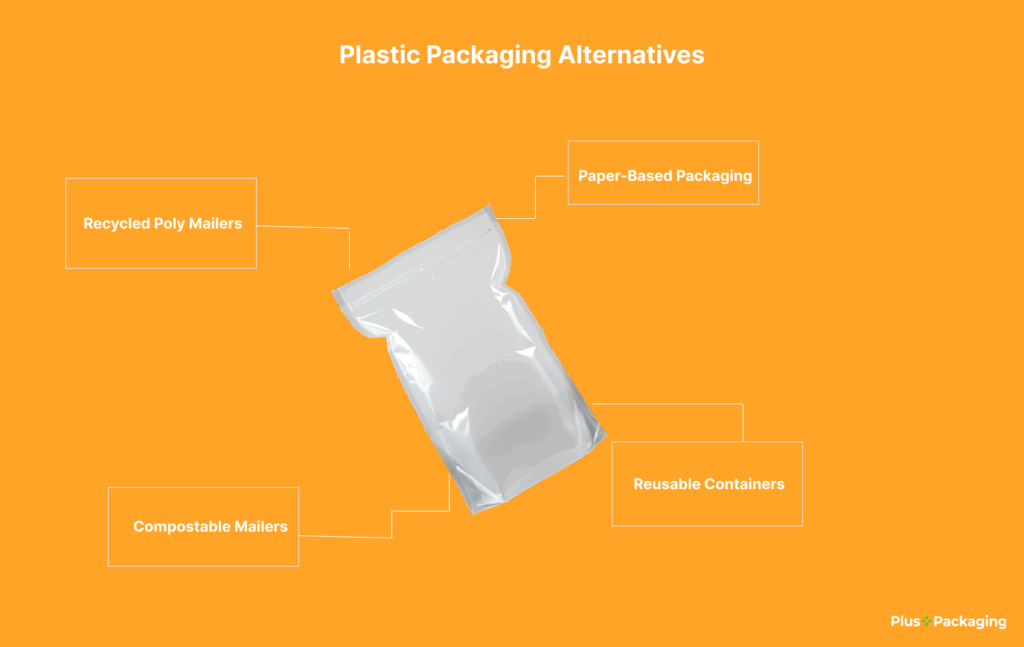

Practical Alternatives to Traditional Plastic Packaging

1. Recycled Poly Mailers

What exactly are they? These mailers look and function just like regular poly mailers, but they’re made from post-consumer plastic waste—often from shopping bags and other film plastics that have been collected, cleaned, and repurposed.

Performance details:

- Just as waterproof as virgin plastic mailers

- Same tear resistance and durability

- Available in multiple thicknesses (typically 2.5-3.0 mil)

- Can be printed with custom designs using water-based inks

- Most include a self-sealing adhesive strip

Cost comparison: Typically 5-15% more expensive than virgin plastic mailers, depending on volume. For a standard 10×13″ mailer, expect to pay around $0.20-0.35 per unit for moderate quantities.

Best for: Clothing, accessories, soft goods, and non-fragile items. They’re particularly good for businesses shipping products that might be exposed to rain or moisture during delivery.

Environmental impact: While still plastic at the end of life, recycled poly mailers reduce the need for new plastic production. Most can be recycled again through store drop-off programs (like at grocery stores), though consumer participation in these programs remains relatively low.

2. Compostable Mailers

What exactly are they? These mailers are typically made from a combination of PLA (polylactic acid, derived from plants like corn) and PBAT (a biodegradable polymer). They’re designed to break down in industrial composting facilities.

Performance details:

- Slightly less stretchy than traditional poly mailers

- Water-resistant but not completely waterproof

- Shelf-stable for 9-12 months when stored properly

- Available in various thicknesses, typically 2.0-2.5 mil

- Can be printed with vibrant, full-color designs

- Most include a second adhesive strip for returns

Cost comparison: Generally 20-40% more expensive than traditional poly mailers. For a standard 10×13″ mailer, expect to pay around $0.30-0.50 per unit for moderate quantities.

Best for: Brands with strongly eco-conscious customers, higher-margin products, and items that don’t require maximum water protection. They work well for clothing, accessories, and lightweight items.

Environmental impact: They break down in industrial composting facilities, usually within 180 days. However, they won’t decompose properly in home compost bins or landfills. The benefit comes when they’re properly composted, which requires customer education.

3. Paper-Based Packaging Options

What exactly are they? This category includes kraft mailers (both flat and padded), corrugated boxes, and paperboard packaging. They’re made primarily from paper, which is renewable and widely recyclable.

Performance details:

- Kraft mailers: Lightweight but less protective than poly or padded options

- Padded paper mailers: Include recycled paper fiber padding for cushioning

- Corrugated mailers: Provide more structure and protection than simple mailers

- All paper options can be easily printed or stamped with branding

- Natural kraft has an artisanal, eco-friendly aesthetic many brands prefer

Cost comparison: Flat kraft mailers are often comparable in price to standard poly mailers. Padded paper mailers typically cost 10-30% more than poly alternatives. For a standard 10×13″ padded paper mailer, expect to pay around $0.25-0.45 per unit.

Best for: Books, prints, flat items, and products that don’t need waterproofing. Padded paper mailers work well for semi-fragile items like small electronics or accessories. Corrugated mailers are good for items needing more structure.

Environmental impact: Paper has a much higher recycling rate than plastic (around 68% for paper vs. 9% for plastic). Most consumers already understand how to recycle paper, making proper disposal more likely. Paper is also biodegradable even in landfill conditions, though recycling is still preferable.

How to Choose the Right Alternative for Your Specific Business

Picking the right packaging isn’t just about being green—it needs to work for your products, your budget, and your operations. Here’s a deeper look at what to consider:

Product Protection Factors

- Weight of your items: Heavier products may need sturdier options like corrugated mailers rather than simple poly alternatives

- Fragility: Electronics, ceramics, and other breakables need cushioning—padded paper mailers or boxes with protective inserts work best

- Moisture sensitivity: If your products can be damaged by water (like printed materials or certain foods), recycled poly offers better protection than paper or some compostable options

- Product shape: Irregularly shaped items might need boxes instead of mailers, or mailers with more flexibility

- Shipping distance: Products traveling internationally or through multiple climate zones need more durable packaging

Cost Considerations Beyond Purchase Price

- Storage space requirements: Some alternatives like corrugated mailers take up more warehouse space, which has its own cost

- Weight affects shipping costs: Paper is heavier than poly or compostable film, potentially increasing your shipping expenses by 5-15%

- Order volume leverage: Larger orders usually mean better pricing—some sustainable options become much more affordable at higher volumes

- Damaged product rates: Sometimes paying more for better protection saves money on replacements and customer service time

- Customer lifetime value: If sustainable packaging increases repeat purchases, the higher cost may be offset by improved retention

Brand Alignment Questions to Ask

- What do your specific customers value most?

Some audiences care deeply about visible sustainability, while others prioritize minimal packaging or premium unboxing experiences - How does this fit your price point?

Premium products can more easily absorb the cost of premium packaging - What story does your packaging tell?

Kraft paper has a natural, artisanal feel; compostable mailers can be printed with vibrant designs that showcase your commitment to innovation - How will you communicate your choice?

The impact is greater when customers understand why you’ve chosen a particular packaging option

Plus Packaging’s Sustainable Options

At Plus Packaging, we’ve developed alternatives that balance performance, sustainability, and cost:

- Recycled Poly Mailers: Our recycled poly options contain at least 30% post-consumer waste and come in multiple sizes and colors. They’re still fully customizable with your branding.

- Compostable Mailers: Made from plant-based materials, our compostable mailers are certified by TUV Austria with the OK-Compost mark, confirming they’ll break down in industrial composting facilities.

- Kraft Paper Mailers: Available in both plain and padded versions, our paper mailers are made from recycled content and can be fully customized with your branding using water-based inks.

Making the Most of Your Sustainable Packaging

Switching to eco-friendly packaging is great, but how you implement it matters too:

Right-Sizing Strategies

Using a mailer that’s too big wastes material and can increase shipping costs. We offer multiple sizes so you can choose the best fit for your products. Some businesses benefit from having 2-3 different sizes on hand rather than a one-size-fits-all approach.

For businesses with varied product sizes, we recommend analyzing your typical shipments and identifying the 2-3 most common size needs. This optimizes both storage space and material usage.

Clear Communication Techniques

Let customers know how to properly dispose of or recycle your packaging. A simple printed message like “This mailer is recyclable with film plastics at grocery store drop-offs” or “Compostable in industrial facilities” goes a long way.

The most effective approach is to print disposal instructions directly on the packaging, but package inserts work too. Some brands include QR codes linking to more detailed recycling information.

Phased Implementation Approach

You don’t have to switch everything overnight. Consider:

- Test with one product line first to gauge customer response and work out any logistics issues

- Use up existing packaging before switching to avoid waste

- Start with your bestsellers where the improved unboxing experience will have the biggest impact

- Time the switch with other brand updates or product launches for maximum marketing impact

Measuring Impact

Track the results of your packaging changes:

- Monitor customer comments about packaging in reviews and social media

- Compare damage rates before and after the switch

- Calculate the actual environmental impact reduction (many suppliers can help with this)

- Survey customers about their perception of your brand before and after

Ready to Make the Switch?

Moving away from conventional plastic packaging doesn’t have to happen all at once. Many businesses start with one product line or when reordering supplies.

The best approach is often to test a few options with your actual products and shipping conditions. What works for someone else might not be perfect for you.

Try Before You Commit

Want to see and feel our sustainable packaging options before you decide? Our sample pack includes:

- 2 sizes of recycled poly mailers

- 2 sizes of compostable mailers

- Flat and padded kraft mailers

- A sample of our custom kraft paper tape

- A detailed information card about each option

Get Expert Guidance

Not sure which option is best for your specific products? Our packaging specialists can help you find the right balance of sustainability, protection, and cost based on what you’re shipping and who your customers are.

Schedule a quick consultation to discuss your packaging needs and get personalized recommendations.