When you’re shipping products to customers, the tape you use might seem like a small detail. But ask anyone who’s had a package burst open during transit or struggled to seal a box properly—tape matters more than you might think.

Good packaging tape does more than just close a box. It protects your products, speeds up your packing process, and can even showcase your brand. But with so many options available, how do you know which type is right for your needs?

In this guide, we’ll walk through the different types of packaging tape, what makes each one unique, and how to choose the best option for your business. We’ll also look at how custom printed tape can turn a basic shipping necessity into a branding opportunity.

How Packaging Tape Works

Before diving into specific types, it helps to understand what makes tape stick in the first place.

Most packaging tapes use pressure-sensitive glue (PSA), which means they stick when you press them onto a surface. The tape itself has three main components:

- The backing material (what gives the tape its structure)

- The adhesive (the sticky part that bonds to surfaces)

- The liner (on some tapes, this is the part you peel off before using)

When choosing tape, you’ll want to consider factors like:

- Adhesion strength – how quickly it sticks (initial tack) and how strongly it bonds over time

- Temperature tolerance – whether it can handle heat, cold, or temperature changes during shipping

- Moisture resistance – important if your packages might be exposed to rain or humidity

- Stretch and flexibility – affects how well it conforms to box edges and corners

- Clarity or color – clear for a clean look, colored for visibility or organization

For businesses looking to make their packaging more memorable, custom printed tape offers a way to add branding to every package you ship.

Types of Packaging Tape

Let’s break down the most common types of packaging tape and what each one does best.

Polypropylene (BOPP) Packing Tape

What it is: The standard clear or tan tape you probably picture when thinking of shipping tape. It has a plastic polypropylene backing with either acrylic or hot-melt adhesive.

Best for: General shipping, lightweight to medium-weight boxes, e-commerce orders.

Advantages:

- Affordable and widely available

- Clear options let package information show through

- Works with standard tape dispensers

- Good for indoor storage and shipping

Limitations:

- Less effective in extreme temperatures

- Not ideal for very heavy boxes

- Can lose adhesion in very cold conditions

Environmental notes: Typically not recyclable and should be removed from cardboard before recycling.

Water-Activated Tape (Kraft Paper Tape)

What it is: Brown paper tape with a starch-based adhesive that activates when wet. Often called gummed tape or kraft tape.

Best for: Secure sealing of cartons, tamper-evident packaging, and eco-friendly shipping.

Advantages:

- Creates an extremely strong bond that becomes part of the cardboard

- Tamper-evident (tears if someone tries to remove it)

- Works well on recycled cardboard

- Recyclable along with cardboard boxes

- Can be custom printed for branding

Limitations:

- Requires a water-activated tape dispenser

- Takes slightly longer to apply than pressure-sensitive tapes

- Not waterproof unless reinforced

Environmental notes: Paper-based water-activated tape is biodegradable and doesn’t need to be removed for cardboard recycling, making it one of the most eco-friendly options.

Reinforced Filament Tape

What it is: Tape with fiberglass strands embedded in the backing for extra strength.

Best for: Heavy boxes, bundling, palletizing, and securing items with sharp edges.

Advantages:

- Extremely strong tensile strength

- Resistant to tearing and splitting

- Good for securing heavy or bulky items

Limitations:

- More expensive than standard packing tape

- Harder to tear by hand (usually requires a dispenser with a cutter)

- Not always clear (often has visible reinforcement strands)

Double-Sided Packaging Tape

What it is: Tape with adhesive on both sides, often with a removable liner.

Best for: Securing packaging inserts, attaching labels, and closing lightweight packages without visible tape.

Advantages:

- Creates clean, invisible seals

- Good for presentation packaging

- Useful for mounting lightweight items inside packages

Limitations:

- Not strong enough for sealing heavy boxes

- More expensive than single-sided tape

- Can be tricky to handle (tends to stick to itself)

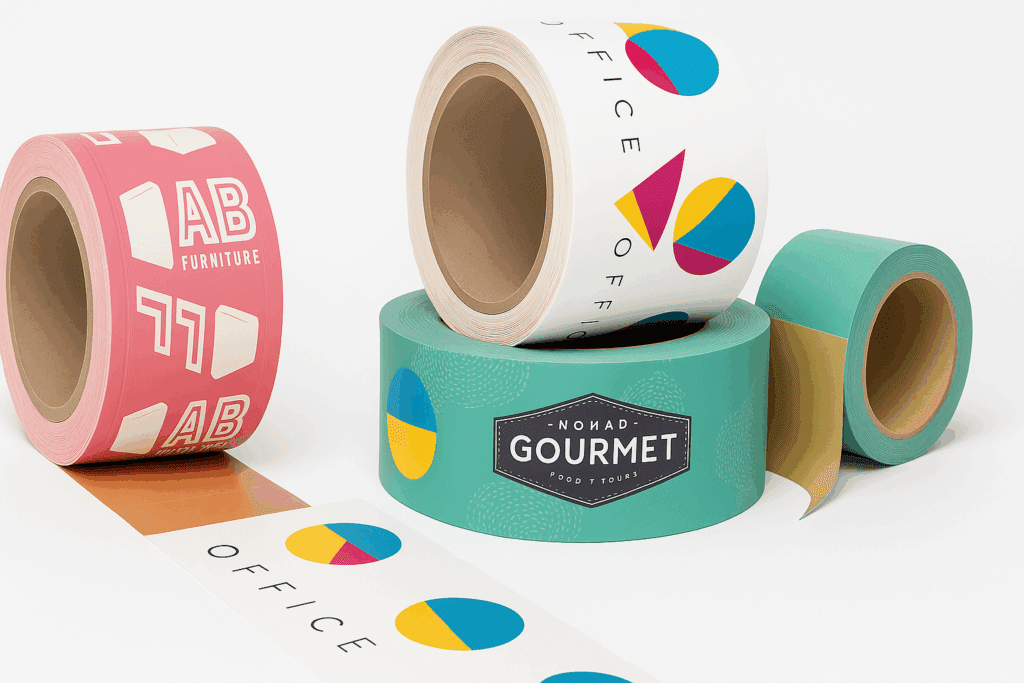

Custom Printed Tape: Turning Packaging into Marketing

While standard tape does the job of sealing packages, custom-printed tape takes things a step further by turning necessary packaging supplies into branding tools.

Benefits of Custom Printed Tape

Brand Recognition: Your logo and colors on every package reinforce your brand identity with each shipment.

Professional Presentation: Custom tape makes packages look more polished and intentional.

Practical Messaging: Beyond just logos, you can include your website, social media handles, or special instructions.

Theft Deterrence: Packages sealed with branded tape are less likely to be tampered with since the seal can’t be replaced inconspicuously.

Cost-Effective Marketing: Compared to other custom packaging elements, printed tape is relatively affordable while still making an impact.

Custom printed tape is available in several formats, including water-activated paper tape (which is both secure and eco-friendly) and polypropylene tape (which offers vibrant color reproduction).

Learn more about custom printed tape options from Plus Packaging

How to Choose the Right Tape for Your Needs

With so many options available, how do you decide which tape is best for your business? Consider these factors:

Box Weight and Contents

- Light packages (under 10 lbs): Standard polypropylene tape is usually sufficient

- Medium packages (10-30 lbs): Consider stronger acrylic adhesive or water-activated tape

- Heavy packages (30+ lbs): Reinforced filament tape or water-activated tape with reinforcement

Shipping and Storage Conditions

- Standard indoor shipping: Most tape types will work fine

- Exposure to cold: Hot-melt adhesive tapes perform better in cold conditions

- Exposure to heat: Acrylic adhesive tapes handle heat better

- Moisture exposure: Water-activated tape (once dry) or PVC tape offers better moisture resistance

Application Method

- Manual application: Consider how easily the tape can be applied by hand

- Dispenser compatibility: Check if the tape works with your existing dispensers

- Packing station efficiency: Water-activated tape dispensers can speed up packing but require initial setup

Unboxing Experience

- Brand visibility: Custom-printed tape adds professionalism and recognition

- Ease of opening: Consider how customers will open the package

- Sustainability messaging: Eco-friendly tape options can reinforce your brand values

Environmental Considerations

- Recyclability: Paper-based water-activated tape can be recycled with cardboard

- Waste reduction: Stronger tapes might allow you to use less material

- Sustainable materials: Look for tapes made with recycled content or renewable resources

Best Practices for Using and Storing Tape

To get the most out of your packaging tape, follow these guidelines:

Storage Tips

- Store tape in a clean, dry area between 60-80°F (15-27°C)

- Avoid direct sunlight, which can degrade adhesives

- Store rolls on their edge rather than flat to prevent edge damage

- Use older inventory first (adhesive quality can deteriorate over time)

Application Best Practices

- Clean, dry surfaces provide the best adhesion

- Apply with firm pressure to activate pressure-sensitive adhesives

- For box sealing, use the H-method: seal the center seam first, then the side flaps

- Allow 2-3 inches of overlap on each end of the seam

- For heavy boxes, consider using multiple strips or wider tape

Dispenser Maintenance

- Keep blade cutters clean and sharp

- Replace worn parts promptly

- For water-activated tape dispensers, clean water brushes regularly and use clean water

Sustainability and Recycling Considerations

As more businesses focus on sustainability, packaging tape choices can play a role in your environmental impact:

- Recyclability: Water-activated paper tape can typically be recycled along with cardboard boxes. Plastic-based tapes should be removed before recycling cardboard.

- Minimizing waste: Using the right strength tape for the job means less material used and less chance of package failures requiring replacement shipments.

- Eco-friendly options: Look for tapes made with recycled content, sustainably sourced materials, or biodegradable components.

- Customer messaging: If you use eco-friendly tape, consider mentioning this in your packaging or marketing materials to highlight your sustainability efforts.

Frequently Asked Questions

What tape is best for heavy boxes? For heavy boxes, water-activated reinforced kraft tape or filament-reinforced tape provides the strongest seal. The reinforcement prevents stretching and breaking under weight.

Is water-activated tape better than polypropylene? Water-activated tape creates a stronger bond that becomes part of the cardboard and is tamper-evident. It’s also typically more eco-friendly. However, it requires a special dispenser and takes slightly longer to apply. For high-volume shipping of medium to heavy boxes, water-activated tape is often worth the investment.

Can I recycle cardboard with tape on it? It depends on the tape. Paper-based water-activated tape can typically be recycled along with cardboard. Plastic-based tapes (like polypropylene or PVC) should ideally be removed before recycling. Some recycling facilities can handle small amounts of plastic tape, but removing it is best practice.

How do I order custom printed tape? To order custom printed tape from Plus Packaging, you can request a quote online. You’ll need to provide your artwork files, specify the tape type and dimensions, and indicate quantity. Lead times typically range from 2-3 weeks, depending on the complexity of your design and the tape type.

What tape works best in cold environments? Hot-melt adhesive tapes generally perform better in cold environments than acrylic adhesives. For extremely cold conditions, specially formulated cold-temperature tapes are available. Water-activated tape also performs well once it has fully dried and bonded.

Making the Right Choice for Your Business

The right packaging tape does more than just seal a box—it protects your products, represents your brand, and can even improve your operational efficiency. Whether you choose standard clear tape for simplicity, water-activated tape for security, or custom printed tape for branding, understanding your options helps you make the best choice for your specific needs.

For businesses looking to enhance their packaging with custom printed tape, Plus Packaging offers high-quality options with low minimum orders and expert design support. Contact us to learn more about how we can help make your packaging stand out.