Mailer boxes and shipping boxes serve different purposes in packaging and shipping. Here’s a quick breakdown:

- Mailer Boxes: Lightweight, sleek, and easy to assemble. Ideal for single-item shipments, subscription boxes, and creating a memorable unboxing experience. Made from thinner corrugated board with a focus on branding and aesthetics.

- Shipping Boxes: Built for durability and heavy loads. Designed for bulk shipments, fragile items, and products requiring extra protection. Made from thick corrugated cardboard with high weight capacity.

Quick Comparison

| Feature | Mailer Boxes | Shipping Boxes |

|---|---|---|

| Primary Use | Lightweight items, subscription boxes | Heavy, fragile, or bulk shipments |

| Material | Thinner corrugated board (B or E Flute) | Thick corrugated cardboard (C Flute) |

| Weight Capacity | Up to 20 lbs | 35–65+ lbs |

| Customization | Full-surface printing, inside & outside | Exterior printing only |

| Assembly Time | Quick and easy | More time required |

| Best For | Apparel, books, cosmetics | Electronics, glassware, heavy items |

| Eco-Friendliness | Minimal materials, recyclable | Recyclable but uses more material |

Key takeaway: Use mailer boxes for lightweight products and branding. Choose shipping boxes for heavier or fragile items needing extra protection.

Choosing the Right Corrugated Box Style

Box Materials and Structure

The performance of packaging largely depends on the construction of corrugated boards and the fluting patterns used.

Types of Cardboard Used

Corrugated cardboard is the backbone of both mailer and shipping boxes, but their specifications vary based on their intended purpose. The Edge Crush Test (ECT) is a key metric that evaluates the board’s strength and how much weight it can handle before buckling.

| Box Type | Common Flute Types | Typical ECT Rating | Weight Capacity |

|---|---|---|---|

| Mailer Boxes | B or E Flute | 23-32 ECT | Up to 20 lbs |

| Shipping Boxes | C Flute | 32-44 ECT | 35-65+ lbs |

Mailer boxes typically use B-flute (42–50 flutes per foot) or E-flute (94 flutes per foot). B-flute strikes a balance between strength and aesthetic appeal, while E-flute, with its thinner profile (1/16 inch), provides a smooth surface ideal for high-quality printing. These choices directly impact the box’s visual design and structural durability.

Click here to learn more about Custom Mailer Boxes!

Box Design and Strength

Shipping boxes, on the other hand, rely on C-flute (approximately 39–43 flutes per foot and 11/64 inch thick) for its excellent crush resistance. Depending on the weight of the contents:

- Lightweight items (up to 20 lbs): Single-wall boards with an ECT rating of around 26 are sufficient.

- Medium-weight items (35–65 lbs): Boards rated between 175# and 200# (approximately 29–32 ECT) are recommended.

- Heavy items (66+ lbs): Materials rated at 275# (about 44 ECT) or higher are necessary for proper support.

Mailer boxes are designed with a focus on visual appeal and ease of assembly, making them perfect for lighter goods. The choice of fluting plays a pivotal role here: while C-flute is unmatched for vertical compression and stacking strength, B-flute and E-flute are preferred for their superior printing surfaces and sleek finishes.

Understanding these differences in materials and design is crucial for evaluating how well a box will protect its contents.

Product Protection Features

After understanding the basics of box construction, let’s dive into how different box types safeguard products during shipping.

Best Uses by Product Type

| Product Type | Recommended Box | Why It Works |

|---|---|---|

| Apparel & Accessories | Mailer Box | Lightweight items need only basic protection. |

| Books & Flat Items | Mailer Box | Keeps items in shape and prevents bending. |

| Glassware & Ceramics | Shipping Box | Offers crush resistance and room for extra cushioning. |

| Electronics & Devices | Shipping Box | Provides better rigidity and guards against impacts. |

| Cosmetics & Essential Oils | Mailer Box | Sufficient for lightweight products that don’t need heavy-duty protection. |

| Heavy Items (35+ lbs) | Shipping Box | Stronger construction prevents damage to heavier goods in transit. |

Mailer boxes work best for lightweight products that don’t require much cushioning. On the other hand, shipping boxes are ideal for heavier or more delicate items, thanks to their sturdier build. Let’s now look at specific ways to ensure products stay safe during transport.

Damage Prevention Methods

To keep your items intact during shipping, pair the right box with these proven protection techniques. The corrugated design of these boxes naturally creates air pockets, which act as insulation against moisture and provide a cushioning effect during transit [4]. For the best results:

- Choose the right size box: Opt for one slightly larger than the product to allow for cushioning.

- Wrap items individually: Use padding materials like bubble wrap or foam.

- Fill empty spaces: Add cushioning materials, such as packing peanuts or crumpled paper, to prevent shifting.

- Seal securely: Use high-quality packing tape to reinforce all seams.

For highly fragile items, consider the double-boxing method. This involves placing the wrapped product in a smaller box, which is then placed inside a larger box filled with cushioning. This extra layer of protection significantly reduces the risk of damage [3].

Additionally, brown corrugated boxes naturally resist moisture, offering added protection against environmental challenges [4].

Cost and Shipping Analysis

Manufacturing Costs

Mailer boxes are generally more economical for lightweight shipments due to their thinner corrugated board and single-piece design, which eliminates the need for extra adhesives or materials. This simplicity helps keep production costs down [1].

| Box Type | Cost Factors | Material Efficiency |

|---|---|---|

| Mailer Box | – Uses thinner board – No adhesives required – Single-piece design |

Ideal for lightweight items |

| Shipping Box | – Thicker corrugated board – Requires tape/adhesives – Multi-piece construction |

Better for bulk or heavy shipments |

While shipping boxes have higher material costs upfront due to their sturdier construction, they can be a smart choice for larger orders or bulk shipments. Their durability also allows for multiple uses before recycling, which can help balance out the initial expense [1].

Carrier Rates and Size Limits

Shipping costs are influenced not just by weight but also by the size of the box. Many carriers, like USPS, have strict size limits that directly affect rates. For instance, USPS enforces a maximum combined length and girth of 108 inches for standard shipments, with an extended limit of 130 inches for USPS Ground Advantage [5].

Mailer boxes are designed to fit within USPS Large Envelope specifications, which range from 11.5 to 15 inches in length, 6.125 to 12 inches in height, and 0.25 to 0.75 inches in thickness. For smaller standard letter shipments, the dimensions should fall between 5 to 11.5 inches in length, 3.5 to 6.125 inches in height, and 0.007 to 0.25 inches in thickness.

On the other hand, shipping boxes are better suited for transporting bulky or heavier products [1].

When deciding on box sizes, keep these considerations in mind:

- Choose dimensions that meet carrier size restrictions.

- Account for any additional packaging materials, such as padding or fillers.

- Factor in product weight, protection needs, and opportunities for consolidating multiple items into a single shipment.

These choices can help optimize shipping costs while ensuring products arrive safely.

Brand Design and Customer Impact

Print Quality and Design Options

Mailer boxes offer a standout advantage for branding, thanks to their ability to feature offset printing on both the inside and outside surfaces. This type of printing ensures precise Pantone color matching and even allows for white ink on kraft paper – something digital printing can’t achieve [6].

| Feature | Mailer Boxes | Shipping Boxes |

|---|---|---|

| Print Surface | Full-surface customization | Limited to exterior only |

| Color Options | Pantone color matching, white ink capability | Basic color options |

| Material Choices | Whiteboard, kraft board, super gloss | Standard corrugated |

| Design Area | Multiple panels for branding | Single outer surface |

Statistics reveal that 7 out of 10 consumers are influenced by packaging design when deciding on a purchase [7]. This highlights how essential it is to invest in high-quality printing and creative design. Combined with strong visual appeal, the unboxing experience becomes a powerful tool for customer engagement.

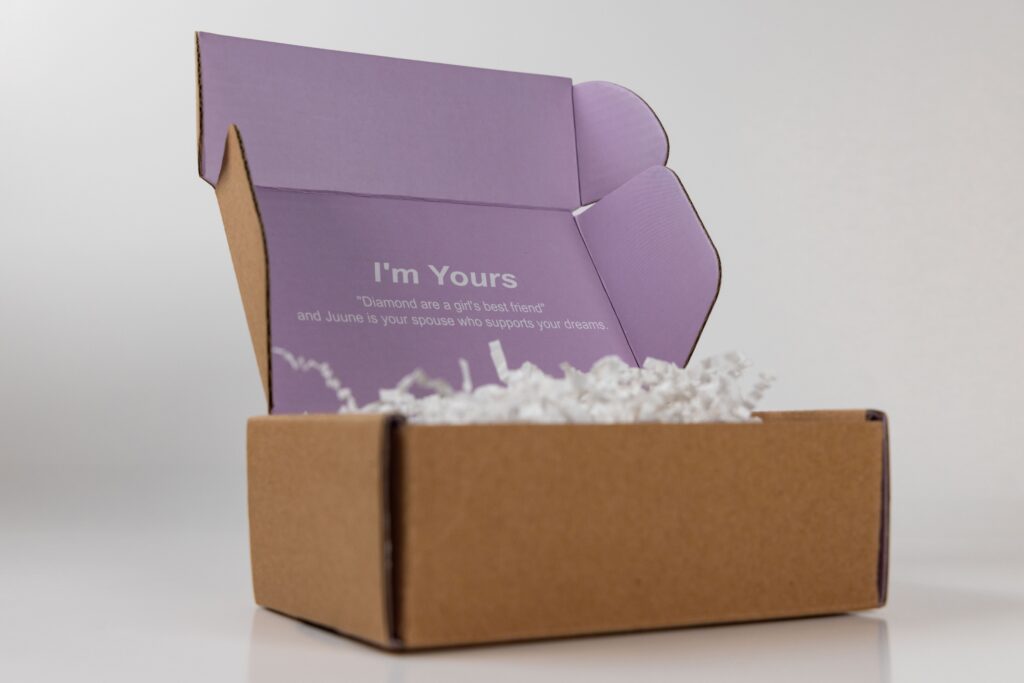

Opening Experience

The unboxing experience doesn’t just complement branding – it can directly impact customer loyalty. For eCommerce brands, every step of the process, from packaging design to the moment the box is opened, contributes to the overall customer journey. Research shows that 60% to 80% of customers are more likely to remain loyal to brands that deliver memorable unboxing experiences [7].

Take, for instance, a small book subscription service. They elevated their unboxing experience by printing literary quotes inside the box lid and including surprise sticker sheets tied to the month’s featured book. This thoughtful touch led to increased social media buzz and stronger customer engagement [8].

Key elements that enhance unboxing include:

- Custom Inserts: Inserts not only protect the product but also create a polished, premium feel [7].

- Brand Storytelling: Interior messaging or designs that reflect the brand’s values and mission.

- Product Presentation: Thoughtful placement and a gradual reveal that builds excitement.

Unboxing videos also play a major role in influencing shoppers, with 55% of consumers saying these videos impact their purchasing decisions [7]. However, it’s important to strike the right balance. One skincare brand faced backlash for using oversized, overly elaborate boxes that customers found wasteful and impractical [8].

Brands can achieve the perfect mix of aesthetics and functionality by focusing on thoughtful design. For example, an indie skincare brand opted for kraft mailer boxes printed with black soy ink. This choice not only showcased its commitment to sustainability but also maintained a sleek, high-end look [8].

Eco-Friendly Features

Recycling and Waste Reduction

Packaging choices play a big role in environmental impact, and both mailer boxes and shipping boxes come with their own sustainability perks. For example, using recycled cardboard instead of virgin materials cuts greenhouse gas emissions by 28.1% [9].

The carbon footprint of a box depends on its size:

| Box Size (inches) | Weight (lbs) | Carbon Footprint (kg CO2e) |

|---|---|---|

| 6 x 6 x 6 | 0.28 | 0.12 |

| 12 x 12 x 12 | 1.08 | 0.46 |

| 24 x 24 x 24 | 4.20 | 1.79 |

Paper products also boast a recycling rate of 68.2% [9], further highlighting the environmental benefits of cardboard packaging. Plus, new advancements in green packaging are making sustainable options even more accessible.

Green Packaging Choices

Eco-friendly packaging options are evolving rapidly. For instance, in 2025, Cairn Coffee Roasters introduced curbside recyclable packaging, balancing product quality with reduced environmental impact for eCommerce shipping [10].

Here are some sustainable material options:

- Recycled cardboard: Cuts carbon emissions by nearly 30% while staying durable [9].

- Corrugated cardboard: Produces 0.94 kg CO2e per kilogram [9].

Real-world examples show how brands are adopting greener practices. Stio now uses branded boxes with high post-consumer waste content, while Ritual has switched to 100% recycled padded mailers containing 20% post-consumer waste [10].

Key factors for sustainable packaging include:

- Material Selection: Using recycled materials can cut carbon emissions significantly [9].

- Disposal Impact: Paper-based packaging is widely accepted in curbside recycling, though recycled poly mailers can also lower carbon footprints despite more complex recycling processes [11].

- Size Optimization: Choosing the right box size reduces material waste and shipping emissions. A 24 x 24 x 24-inch box produces 15 times more CO2e than a 6 x 6 x 6-inch box [9].

Even premium brands are embracing sustainability. Cocofloss, for instance, uses eco-friendly inner packaging to combine quality with environmental responsibility [10].

Click here to learn more about Custom Shipping Boxes!

Warehouse and Packing Efficiency

Box Setup Time

Mailer boxes are much simpler to assemble, which speeds up the packing process. EcoEnclose explains:

“Mailers are fast to fill. All you have to do is open the mailer, put the product inside, peel the paper strip, seal it, and send it to your customers.” [2]

This streamlined process not only increases warehouse productivity but also helps cut labor costs. On the other hand, shipping boxes require more steps to assemble, which can slow down fulfillment operations. The time saved with mailers can play a big role in improving overall efficiency.

Conclusion: Making Your Box Choice

Choosing between mailer boxes and shipping boxes comes down to what works best for your business and the products you’re shipping. If you’re dealing with lightweight items like clothing, books, or cosmetics, mailer boxes are often the go-to. They’re compact, cost-effective, and support faster order processing – perfect for businesses handling high volumes of eCommerce orders.

Here’s a quick comparison to help you decide:

| Factor | Mailer Boxes | Shipping Boxes |

|---|---|---|

| Best Products | Lightweight, flat items (e.g., apparel, books, cosmetics) | Heavy, fragile, or multiple items |

| Protection Level | Standard protection; may need extra padding | High protection with sturdy walls |

| Shipping Costs | Lower rates; compatible with USPS flat-rate options | Varies based on size and weight |

| Assembly Speed | Quick and easy setup | Takes more time to assemble |

| Storage Impact | Requires minimal storage space | Needs more warehouse space |

Mailer boxes also use fewer materials, fitting into the growing demand for eco-conscious packaging. In fact, research highlights that 82% of consumers are willing to pay more for environmentally friendly packaging [2]. This makes them a smart choice for brands looking to align with sustainability trends.

Don’t forget to think about your brand’s unboxing experience. Both mailer and shipping boxes can be customized, but shipping boxes often allow for more elaborate designs and inserts. This can be a game-changer for direct-to-consumer brands aiming to leave a lasting impression [1].

FAQs

How do I decide between mailer boxes and shipping boxes for my eCommerce business?

When deciding between mailer boxes and shipping boxes, a few important factors come into play:

- Product Size and Weight: Mailer boxes work well for smaller, lightweight items. On the other hand, shipping boxes are better for larger, heavier products or when shipping multiple items together.

- Durability Requirements: Shipping boxes are made from thicker corrugated material, offering stronger protection for fragile or bulky goods during transit.

- Customer Experience: If presentation matters, mailer boxes are a great choice. They can be customized to create a polished look that enhances the unboxing experience.

- Cost Considerations: Take into account the cost of materials, shipping, and any customization. Make sure your packaging choice fits both your budget and business objectives.

By weighing these factors, you can choose the packaging option that not only protects your products but also leaves a positive impression on your customers.

What are the environmental differences between mailer boxes and shipping boxes?

Mailer boxes and shipping boxes each have distinct effects on the environment, largely influenced by their materials, size, and purpose. Mailer boxes are generally crafted from lightweight materials and tend to be smaller, which means less material is used and transportation emissions are lower. Shipping boxes, however, are often larger and built for durability, requiring more materials and potentially increasing their environmental footprint.

To reduce their impact, opt for recyclable materials, compostable alternatives, or boxes made from recycled content for either type. Additionally, selecting appropriately sized packaging can cut down on waste and support more eco-friendly practices.

How can I create a memorable unboxing experience with mailer boxes for my customers?

To craft an unforgettable unboxing experience with mailer boxes, focus on blending thoughtful design with a personal touch. Custom mailer boxes featuring bold colors, distinctive patterns, and clear branding can instantly grab attention and set your packaging apart. Elevate the interior by adding small yet impactful details – think printed designs, branded tissue paper, or even a surprise message tucked inside the lid.

For an extra layer of connection, incorporate personalized elements. A handwritten thank-you note, a discount code for a future purchase, or a small freebie can genuinely surprise and delight your customers. These little gestures don’t just enhance the unboxing moment – they create a lasting impression that strengthens your brand’s connection with its audience.

Looking for personalized packaging?

Get your business a makeover with our tailored solutions for your unique needs!